PRODUCT & SERVICE Device Programmer

- MINATO

- PRODUCT & SERVICE

- Device Programmer

- Auto Programming System

- PH-M100A (Automated)

PH-M100A (Automated)

PH-M Series

High-performance automated programming system equipped with high-speed Gang Programmer "MODEL 508PH".

16 sockets IC programming fully automated system equipped with two high-speed Gang Programmers MODEL 508PH. With the integrated design of MODEL508PH and PH-M100A, all operations are possible from the operation panel.

Features

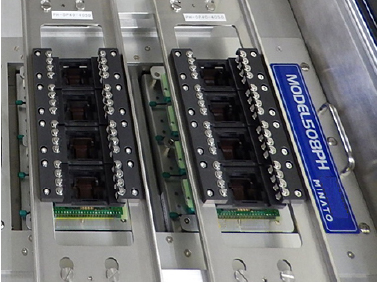

MODEL508PH

Equipped with two high-performance Gang Programmers MODEL 508PH developed for mounting on automated machines. Supports from small capacity flash memory to large capacity memory such as eMMC and NAND.

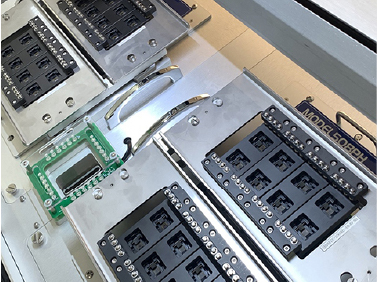

eMMC dedicated socket unit

When using the socket unit for eMMC, 16 sockets x 2 sites, 32 sockets in total can be programmed simultaneously.

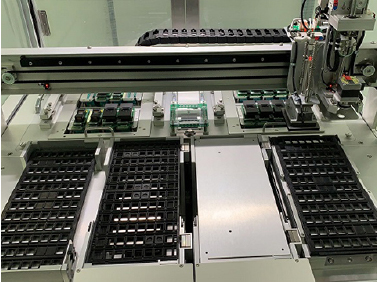

Tray Arrangement

20 JEDEC trays can be stored. Available for continuous running of 20 trays maximally.

Auto Teaching

Fine adjustment can be performed easily and automatically with the high performance CCD camera.

During automatic operation, correct the position of each IC and insert it correctly into the socket.

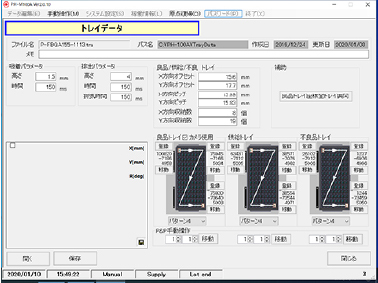

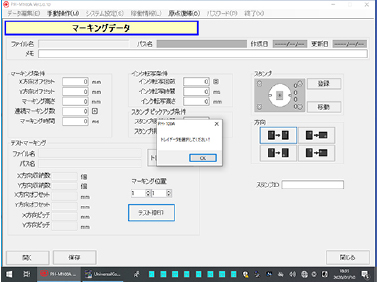

Operating Screen

Program data, coordinate data, and marking data can be collectively managed as task data.

The software supports Japanese, English, and Chinese languages. Barcode reader is also available.

Simple Marking Function

A combination of dot marks, letters and numbers are available.

(The number of characters depends on the IC device size)

Specification

Device programmer

| Device programmer | MODEL508PH (8 socket) x 2 units |

|---|---|

| Interface | USB3.0 |

| Programmer buffer memory | Standard 1024Gbit |

| Target IC device |

eMMC, eSD, GB-NAND, MoviNAND, i-NAND, NAND, OneNAND, Flash built-in MCU, NOR, etc.

|

| Operation Log | Automatically save each lot in text format |

Handler

| Target IC package | TSOP・SOP・BGA・QFP |

|---|---|

| Target socket adapter | Open-top (OT socket adapter) |

| IC device handling |

X, Y, Z, θ 4-axis 2-phase pulse motor + belt drive X-axis minimum resolution: 4.5 μm/pulse Y-axis minimum resolution: 4.3 μm/pulse Z-axis minimum resolution: 5.4 μm/pulse |

| IC device handling capacity | 900 [UPH] UPH = Units per hour *Excluding work sequences such as tray transfer |

| Coordinate data registration method |

Manual method

X-Y, Theta coordinates: Visual setting with dedicated pad and dedicated jig Z coordinate: Auto teaching Fully automatic positioning method Original system by image processing |

| Image inspection function |

Automatic correction of IC device transport posture by CCD camera image processing.

|

| Supply method |

Tray loader method (standard)/tube (option/under development)/tape (option/under development)

Target tray: JEDEC (size: 315.8mm x 135.8mm for automatic transfer *Vacuum pick site is necessary in the center)/EIAJ Number of storage 20 supplies, 20 storage, 1 defective storage, 3 empty tray buffers. |

| IC device marking (Option) |

Room temperature curing type Shachihata TAT strong adhesion ink + Marking unit, supports dot marks and character marks.

|

| Control | Windows(R) 10 |

| User interface |

LCD panel (PLC monitor, PC), keyboard, mouse

|

| Network compatible | Ethernet |

| Model switching time |

10 minutes or less *However, IC program data transfer time is not included.

|

| Air supply |

0.45Mpa-0.55Mpa 50l/min *Limited to dry air

|

| Power supply | ACIN :AC100V/AC220V 50/60Hz 15A Can be changed according to the installation location. |

| Machine size/weight |

(D) 1000x (W) 965x (H) 1500 (mm) About 450Kg

* Does not include protrusions, PC, or monitor. |